Fasteners and Machining: Incorporating Accuracy and Stamina in Manufacturing

Fasteners and Machining: Incorporating Accuracy and Stamina in Manufacturing

Blog Article

Browsing the World of Fasteners and Machining: Techniques for Precision and Speed

In the intricate realm of bolts and machining, the pursuit for precision and speed is a perpetual difficulty that demands precise interest to information and critical planning. From understanding the varied range of bolt kinds to choosing optimal products that can withstand extensive demands, each action in the process plays a crucial role in accomplishing the wanted outcome. Precision machining strategies additionally elevate the intricacy of this craft, needing a fragile equilibrium in between technological know-how and cutting-edge methods. As we look into the approaches that can enhance both rate and efficiency in this domain name, the interaction in between top quality control measures and functional excellence arises as a critical centerpiece.

Understanding Bolt Types

When selecting bolts for a project, understanding the numerous types offered is essential for making sure optimal efficiency and dependability. Fasteners are available in a vast array of kinds, each developed for specific applications and requirements. Bolts are utilized with nuts to hold materials together, while screws are flexible bolts that can be made use of with or without a nut, depending upon the application. Nuts, on the various other hand, are inside threaded fasteners that companion with screws or screws, offering a secure hold. Washing machines are essential for distributing the load of the fastener and protecting against damages to the product being fastened. Furthermore, rivets are long-term bolts that are optimal for applications where disassembly is not called for. Comprehending the differences in between these fastener types is crucial for choosing the right one for the job, making sure that the connection is solid, durable, and dependable. By picking the appropriate bolt kind, you can maximize the efficiency and longevity of your project - Fasteners and Machining.

Selecting the Right Products

Recognizing the relevance of picking the best materials is critical in making sure the optimal efficiency and dependability of the chosen bolt types discussed formerly. When it pertains to bolts and machining applications, the product option plays a crucial role in figuring out the overall toughness, sturdiness, deterioration resistance, and compatibility with the designated setting. Different materials supply varying residential properties that can substantially affect the performance of the bolts.

Typical products utilized for fasteners consist of steel, stainless steel, titanium, aluminum, and brass, each having its distinct staminas and weaknesses. Steel is renowned for its high toughness and resilience, making it appropriate for a wide range of applications. Selecting the right material entails thinking about variables such as stamina demands, environmental conditions, and budget plan constraints to ensure the wanted efficiency and longevity of the fasteners.

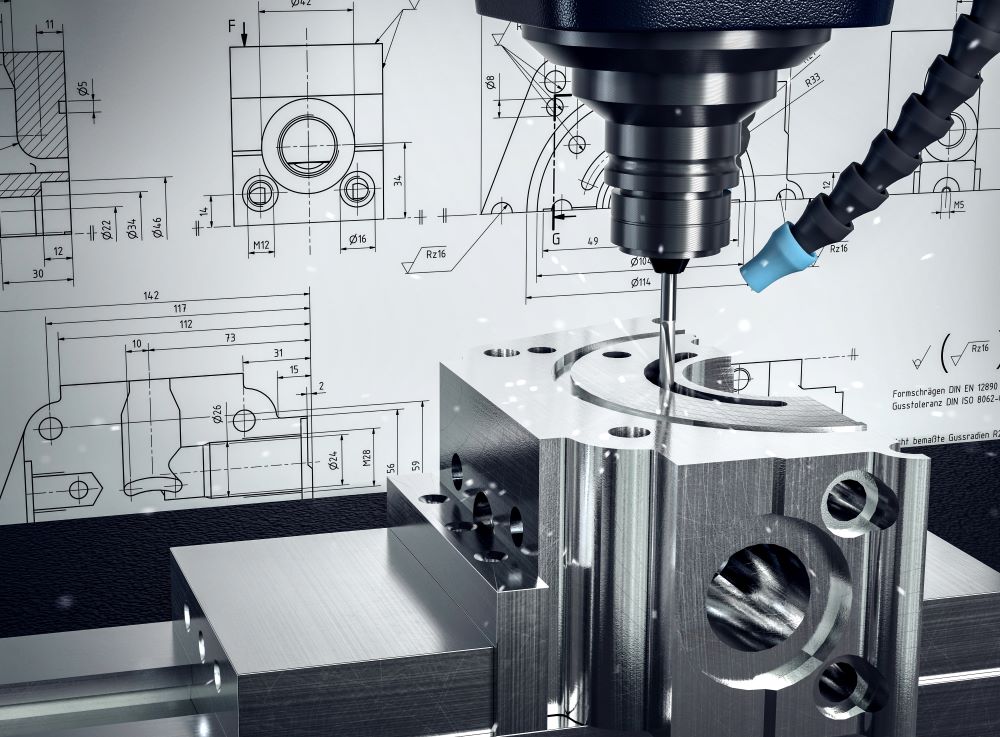

Precision Machining Techniques

In enhancement to CNC machining, various other precision techniques like grinding, transforming, milling, and exploration play vital functions in bolt manufacturing. Grinding assists attain fine surface area coatings and tight dimensional tolerances, while turning is often made use of to create cylindrical components with accurate sizes. Milling and boring procedures are necessary for forming and creating holes in fasteners, ensuring they satisfy specific specs and feature appropriately.

Enhancing Rate and Performance

To maximize fastener production procedures, it is Look At This essential to improve operations and carry out efficient methods that complement accuracy machining techniques. Automated systems can take care of recurring tasks with precision and rate, permitting workers to concentrate on even more facility and value-added activities. By integrating these approaches, suppliers can achieve an equilibrium between rate and precision, inevitably enhancing Bonuses their affordable side in the bolt sector.

Quality Assurance Measures

Carrying out strenuous high quality control steps is critical in ensuring the integrity and uniformity of bolt items in the manufacturing process. Fasteners and Machining. Quality control actions encompass various stages, beginning from the selection of raw materials to the last inspection of the finished bolts. This entails assessing variables such as material toughness, longevity, and composition to assure that the fasteners fulfill market criteria.

Normal calibration of devices and equipment is important to maintain uniformity in manufacturing and ensure that fasteners fulfill the necessary resistances. Applying stringent procedures for identifying and dealing with non-conformities or issues is vital in protecting against substandard products from getting in the marketplace. By establishing a thorough quality control framework, producers can copyright the online reputation of their brand and supply fasteners that meet the highest possible criteria of efficiency and toughness.

Verdict

In the complex realm of bolts and machining, the mission for accuracy and rate is a continuous difficulty that requires careful focus to detail and tactical planning. When it comes to bolts and machining applications, the product option plays a vital duty in determining the overall stamina, resilience, corrosion resistance, and compatibility with the designated atmosphere. Precision machining entails various innovative methods that make sure the tight tolerances and specs required for bolts.In enhancement to CNC machining, other precision strategies like grinding, turning, milling, and exploration play crucial functions in fastener manufacturing.To optimize fastener manufacturing processes, it is essential Fasteners and Machining to enhance operations and implement efficient methods that enhance accuracy machining strategies.

Report this page